In the high-octane world of Formula 1, silence is rarely empty. Usually, it is heavy with tension, frustration, or—in the rarest of cases—the suppressed energy of a brewing storm. For the Tifosi, the 2025 season was a deafening silence of the worst kind. It was a parade of disappointments, a year where the legendary Prancing Horse didn’t just stumble; it fell.

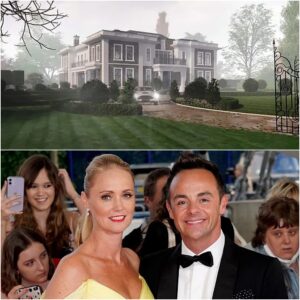

Zero victories. A humiliating fourth-place finish in the Constructors’ Championship, trailing behind McLaren, Mercedes, and Red Bull. For Lewis Hamilton, the sport’s most decorated knight who arrived in Maranello as the messiah, it was a statistical nadir: the first season in his entire illustrious career without a single podium finish.

To the outside world, the situation looked dire. Critics sharpened their knives, questioning the Briton’s move and Ferrari’s competence. Charles Leclerc, who managed to drag the flawed SF25 to the podium seven times, looked increasingly like a man carrying the weight of a crumbling empire. But while the paddock whispered about Ferrari’s demise, the lights at the Maranello factory were burning late into the night. They weren’t fixing the old car; they were building a monster.

We now know what Lewis Hamilton’s stoic silence meant. He wasn’t resigned to defeat; he was waiting for the weapon that was being forged in the fires of “Project 678.” Ferrari is about to unleash a technical revolution for the 2026 season, one based on a gamble so radical it defies three decades of racing logic.

The Material Revolution: Why Steel?

For over thirty years, the standard in Formula 1 engine manufacturing has been aluminum. It is lightweight, predictable, and industry-standard. Every engineer knows how it behaves, and every team uses it. But for 2026, Ferrari has decided to tear up the rulebook.

At the heart of their new power unit lies a decision that sounds counter-intuitive to any racing purist: they are replacing the aluminum cylinder heads with a steel alloy.

In a sport obsessed with shedding every milligram of weight, opting for a heavier metal like steel seems like madness. However, this is a calculated risk driven by the unique demands of the upcoming 2026 regulations. The new era of F1 requires a drastic 50/50 split between thermal power (the combustion engine) and electrical power. This delicate balance means that the internal combustion engine (ICE) must work harder, hotter, and more efficiently than ever before to extract every kilowatt of energy.

Steel offers something aluminum cannot: invincibility under pressure. The new alloy, which reportedly includes copper and ceramic compounds, possesses a mechanical resistance far superior to aluminum. It allows the engine to handle catastrophic internal pressures and combustion temperatures without warping or deforming. While rivals are playing it safe with materials that might struggle under the new “super-combustion” requirements, Ferrari is building a block designed to withstand hellfire.

3D Printing the Impossible

The obvious question arises: How do you build a racing engine out of steel without making it an anchor that drags the car down? The answer lies in a manufacturing process that borders on science fiction.

Ferrari is not casting these engines in traditional molds. They are printing them.

Using a technique known as DMLS (Direct Metal Laser Sintering), Maranello engineers are building the engine layer by layer using high-power lasers to melt metal powder. This is not just a fancy production method; it is the only way to achieve the internal geometries Ferrari has designed.

By 3D printing the cylinder heads, Ferrari can create complex internal cooling channels that would be physically impossible to cast. These channels fit to the millimeter, winding through the structure to provide cooling exactly where it is needed most. This granular control over thermodynamics allows the steel engine to operate at peak performance without melting down.

This innovation—spearheaded in collaboration with the Austrian engineering firm AVL—solves the weight problem by removing material from everywhere it isn’t needed, creating a structure that is structurally dense but spatially efficient.

The Aerodynamic Domino Effect

The genius of this engine design is not just in the horsepower it produces, but in the freedom it grants the aerodynamicists. Because the steel alloy and the 3D-printed cooling channels dissipate heat so efficiently, the engine requires less external cooling.

Less cooling means smaller radiators. Smaller radiators mean the car’s sidepods (pontoons) can be significantly narrower.

In modern Formula 1, aerodynamics is king. By shrinking the sidepods, Ferrari opens up a massive amount of space for clean airflow to travel to the rear of the car. This reduces drag, increases top speed, and improves the efficiency of the DRS—all without touching the sensitive floor or diffuser areas. While other teams might be forced to run bulky cooling packages to keep their aluminum engines from overheating, Ferrari’s “steel heart” could allow for a sleek, razor-thin chassis that cuts through the air like a knife.

The Rivals’ “Legal Cheat”

Ferrari’s radical approach becomes even more significant when contrasted with what their rivals are doing. During the latter half of 2025, whispers began to circulate that Mercedes and Red Bull had found a loophole—a “magic trick” within the regulations.

The FIA rules state that the engine’s compression ratio must not exceed 16:1 when measured at ambient temperature. Mercedes and Red Bull allegedly designed their engines using materials with specific thermal expansion coefficients. When cold (during inspection), the ratio is a legal 16:1. But once the engine hits race temperatures of 100°C or more, the materials expand, subtly changing the geometry of the combustion chamber to achieve an effective compression ratio of 18:1.

This “variable compression” trick yields massive benefits: better combustion, more power, and less strain on the electrical hybrid system. It is a brilliant piece of engineering skirting the edge of legality.

Ferrari, along with Honda and Audi, formally protested this, asking the FIA to close the loophole. The FIA refused, declaring the trick legal.

Faced with this rejection, Ferrari had a choice: copy the trick and be a year behind, or double down on their own philosophy. They chose the latter. While Mercedes and Red Bull are relying on a clever interpretation of the rules, Ferrari is betting on “pure engineering”—structural superiority that doesn’t need to hide in the fine print.

The Ultimate Gamble

There is no safety net for Ferrari. Project 678 is an “all-in” move. The risks associated with this new technology are terrifying.

Steel cylinder heads operating at these temperatures and pressures are uncharted territory in F1. If a microscopic crack appears, if the laser-sintering process has a single flaw, or if the cooling calculations are off by a fraction, the engine won’t just lose power—it will fail catastrophically.

With the regulations limiting drivers to just four engines for the entire 24-race season, reliability is paramount. A fragile engine doesn’t just mean a DNF (Did Not Finish); it means grid penalties that can ruin a championship bid before the summer break.

Ferrari is walking a tightrope. One side is dominance—a car with a bulletproof engine and superior aerodynamics that leaves the field in the dust. The other side is disaster—a season of smoke, failures, and the definitive end of championship hopes for Hamilton and Leclerc.

The Reveal

The world will get its first look at this audacious machine on January 23rd at the Fiorano test track. Reports suggest the car’s assembly will be completed a mere 24 hours before the launch, a schedule that speaks to the frantic, obsessive precision of the project.

Lewis Hamilton’s silence was not passivity. It was the quiet confidence of a man who knows he is holding an ace card. He didn’t come to Italy to drive a slightly better car; he came to drive a revolution. Whether that revolution ends in a shower of champagne or a cloud of steam remains to be seen, but one thing is certain: Ferrari is no longer content to just participate. They are rewriting the physics of the sport to win.

The prancing horse is ready to kick again, and this time, it has hooves of steel.