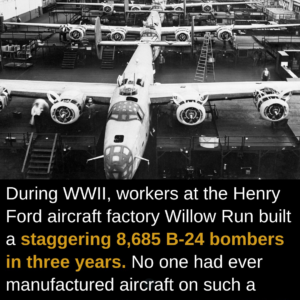

The Willow Run bomber plant made aviation, industrial and social history—along with new B-24s by the hour.

By mid-1944, the Willow Run assembly plant was producing one B-24 per hour—accounting for half of all B-24s assembled that year.

Some 12,000 women worked at the Willow Run bomber plant, each paid the same 85 cents an hour as their male counterparts.

Architect Albert Kahn boasted that the Willow Run plant would be “the most enormous room in the history of man.”

Out of sheer necessity, Willow Run’s 42,500-member workforce became a model of diversity for future generations.

Skeptics scoffed at the idea that Ford Motor Co. could mass-produce heavy aircraft. “You can’t expect a blacksmith to make a watch overnight,” sniffed Dutch Kindelberger, president of North American Aviation.

General Motors produced the Chevrolet Corvair at the Willow Run plant from 1959 to 1969.

Sixty-seven feet long, the B-24 had 450,000 parts and 360,000 rivets in 550 sizes, and it weighed 18 tons.

President Roosevelt stunned millions of listeners when he announced during a May 26, 1940, fireside chat that government must “harness the efficient machinery of America’s manufacturers” to produce 50,000 combat aircraft over the next 12 months to confront the “approaching storm” of global war. FDR’s goal exceeded the total of all planes built in the U.S. since the Wright brothers’ 1903 flight at Kitty Hawk, NC, and he challenged the aviation industry to match that number in succeeding years. As he spoke, the country had fewer than 3,000 warplanes in its arsenal, most obsolete.

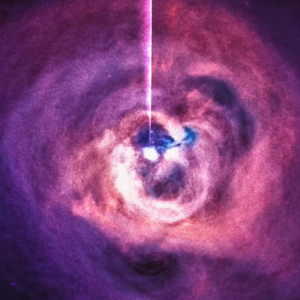

The president and his advisers were convinced that long-range, high-altitude heavy bombers would be the decisive weapon in a war dominated by air power and industrial muscle. Their shopping list included 12,000 of these aerial battleships to attack Germany’s heartland, hammering military installations, bridges, factories, rail yards, fuel storage tanks and communications centers. The “heavies” of choice were the B-17 Flying Fortress from Boeing Airplane Co. and the B-24 Liberator from Consolidated Aircraft.

The B-17 had a six-year history of design, development, testing and limited production. The twin-finned, high-winged B-24 with its dual bomb bays and tricycle landing gear debuted in 1939 as a repurposed land model of Consolidated’s bulky flying boats. Handcrafted versions were pressed into service in England, but the San Diego company lacked resources and methods for high-volume production of the largest, most complex airplane ever designed. Still, aviation industry leaders scoffed when the War Department chose Ford Motor Co. to mass-produce Liberators.

Automobiles of the era had 15,000 parts and weighed around 3,000 pounds. Sixty-seven feet long, the B-24 had 450,000 parts and 360,000 rivets in 550 sizes, and it weighed 18 tons. Skeptics dismissed mass production of a plane this enormous and advanced as a carmaker’s fantasy that would crash and burn when repeated design changes disrupted assembly lines and junked expensive tooling. “You can’t expect a blacksmith to make a watch overnight,” sniffed Dutch Kindelberger, president of North American Aviation.

Ford proved them wrong, not easily nor entirely, during a 2.5-year production run in a 3.5-million-square-foot factory built over Willow Run Creek near Ypsilanti, MI. The massive plant turned out 8,645 Liberators vs. 9,808 manufactured by four factories of Consolidated, Douglas Aircraft, and North American Aviation. Together they produced more of the slab-sided behemoths than any American warplane ever.

At peak production, B-24s sheathed in 4,200 square feet of bonded aluminum rolled out the door every hour. Four 1,200-hp Pratt & Whitney R-1830 Twin Wasp engines assembled by Buick Motor Division shook the earth as the newly minted war machines cast aloft on test flights. The ungainly aircraft flew faster (300 mph) than the sleeker B-17, carried heavier payloads (four tons of bombs, later increased to six tons), and had greater range (3,000 miles).

Rugged and versatile, Liberators served in every theater of the war with 15 Allied air forces, stalking and destroying German U-boats in Atlantic shipping lanes, “flying The Hump” from India over the Himalayas to bring critical fuel and supplies to the besieged Chinese army, and dropping special agents into France and the Low Countries to organize sabotage operations against Nazi occupiers. Winston Churchill called his specially outfitted B-24 the Commando.

The Whole Plane or Nothing

Ford production chief Charles Sorensen, driving force behind the B-24 program, possessed a crusader’s faith and fervor in the primacy and benefits of mass production, and had the bona fides to back it up. A rough-hewn, hard-charging martinet, “Cast Iron Charlie” played a principal role in conceiving and designing the world’s first moving assembly line at Ford’s Highland Park plant bordering Detroit. He went on to oversee operations at the company’s River Rouge complex where 100,000 workers could produce 10,000 cars a day, from raw materials to finished products. The 60-year-old production czar viewed mass production of B-24s as the crowning achievement of his career.

During a January 1941 inspection tour of the Consolidated San Diego plant with Edsel Ford, gentlemanly 45-year-old company president and son of cantankerous autocrat Henry Ford, Sorensen belittled the operation’s deliberate, labor-intensive procedures. “There was no sequence or orderly flow of materials, no sense of forward motion, no reliance on machined parts,” he said. “They were producing a custom-made plane put together as a tailor would cut and fit a suit of clothes. No two were alike.”

Sorensen stayed up all night formulating a B-24 assembly process on the backs of Coronado Hotel placemats. His sketches embraced the two fundamentals of mass production: standardized, interchangeable parts and continuous, orderly flow punctuated by stops at assembly stations where workers and machines performed repetitive tasks.

By 4 a.m. he had configured floor space and time requirements for sequential assembly of the plane’s principal sections, each fabricated in choreographed progression through separate, self-contained cells. Sections included center wing, outer wings and wing tips, fuselage, nacelles, flight deck, nose and tail. Overhead cranes would hoist completed sections onto the final assembly line for joining into a finished aircraft, the same way cars were put together, but on a grand scale in a massive new plant.

Sorensen reviewed his concept at breakfast with Edsel, who responded enthusiastically to its vision and boldness and initialed it on the spot, as did Henry II and Benson, his two sons accompanying him on the trip. They presented the plan to Consolidated President Reuben Fleet and George Mead, procurement director for the Advisory Council for National Defense, who countered with an offer to produce a thousand sets of wings. “We’ll build the whole plane or nothing,” Sorensen barked, accompanied by the audacious claim that Ford would assemble new B-24s every hour.

The whole plane it would be, with the agreement that Ford would truck B-24 parts and finished sections called knockdowns to Consolidated plants in San Diego and Fort Worth and to Douglas Aircraft in Tulsa. Consolidated maintained control over design changes and so did the Army Air Corps (retitled U.S. Army Air Force in June 1941). Ford had no say in the matter; production chaos ensued.

For the next six months, Sorensen shuttled 70-man teams of engineers and draftsmen back and forth on 2,300-mile trips from Ford headquarters to the Consolidated works in San Diego to immerse themselves in B-24 design, engineering, parts and components. To their dismay they discovered that engineering drawings for the big bomber were useless—incomplete and filled with discrepancies and unfamiliar signs and symbols. An unknown number dwelt in the memories of plant foremen.

Cast Iron Charlie had two Liberators flown to Dearborn where they were dismantled piece by piece. A thousand-member tool design group worked around the clock seven days a week for almost a year to create three-dimensional schematics of the plane’s 30,000 separate components, generating five million square feet of blueprints in the process. Their work guided custom designs of 1,600 machine tools and 11,000 fixtures, some 60 feet tall, that would stamp, mill, drill, broach and grind parts to thousandths-of-an-inch tolerances, each with repeatable precision.

The Most Enormous Room in History

While this was unfolding, Sorensen retained renowned industrial architect Albert Kahn to design a factory that would adapt Ford’s automotive assembly techniques to mass production of a giant aircraft. The worksite Sorensen chose was a 1,875-acre Ford-owned tract that had been a farm camp for boys whose fathers were killed or disabled in World War I. Kahn had designed the Rouge and hundreds of other manufacturing facilities over a long and storied career. Not given to understatement, he proclaimed that the one-level superstructure would be “the most enormous room in the history of man.”

He may have been right. More than 3,200 feet long and 1,279 feet across at its widest point, the plant’s 80-acre interior exceeded the Empire State Building’s floor space by 20 percent. One pundit referred to it as “a sprawling mass of industrial ambition.” Folklore has it that Henry Ford decreed that the eastern perimeter of the windowless, L-shaped edifice not spill over into Wayne County, home to Detroit and all those rascally Democrats and union organizers.

Construction began April 18, 1941. Thirty-eight tons of structural steel, five million bricks, and six months later, the $65-million colossus began churning out parts while equipment was still being installed and roof and walls remained unfinished. The first section of an 850-acre airfield adjoining the plant opened three days prior to Pearl Harbor, signaling the Liberator’s primary war mission: long-range flights over Pacific waters to bomb networks of enemy-held islands stretching from Australia and Guadalcanal to the Japanese mainland some 3,000 miles distant.

Media coverage hyped by Ford and military publicists wove extravagant tales of a mammoth industrial citadel where 100,000 dedicated workers would produce hundreds of Liberators each week to roar across the oceans and obliterate enemy sources and seats of power. Before the first employee was hired, the factory stood as a national symbol of America’s fearsome production prowess.

Willit Run

Reality proved otherwise. No B-24s were mass-assembled until the final weeks of 1942, more than a year after the plant opened, when 56 came off the line. Deemed unfit for combat, they were assigned to training bases, reconnaissance patrols and transport duties. Expectations were crushed and the sarcastic appellation Willit Run gained wide circulation. Sorensen blamed delays on doing business with the government, treading through a maze of conflicting priorities and regulations, rancorous labor relations and wildcat strikes, housing shortages and erratic delivery of essential materials.

All true, but he didn’t mention the hard steel dies he authorized, the same types used to slam auto parts into shape, damaged and defaced the softer aluminum, a metal comprising 85 percent of B-24 content. Dies and machine tools were tossed out and redesigned, wasting precious time and millions of dollars.

The housing shortage Sorensen complained about arose from his choice of a sparsely populated rural setting 30 miles west of Detroit’s labor pool—“an island in Michigan mud,” as one writer viewed it. Every available room within miles was rented, including those with eight-hour shifts called hot beds. Long car rides from Detroit over lumpy roads and in overcrowded buses discouraged thousands of employees who left for jobs closer to home. Many fled after their first day, traumatized by the smell, constant clanging and motion of machinery, and overpowering size of the place. Those who stayed hunkered down in tarpaper shacks, tents, garages, and beat-up trailers and jalopies.

Using lumber from hundreds of trees cut down to clear the site, contractors built temporary dormitories for single men and women, trailer parks, and prefabricated flat-top housing for families that, by the end of 1943, could house 15,000 employees. The War Department pitched in with funds for the Detroit Industrial Expressway, linking the city to the plant. Years later, that stretch would become a section of I-94.

Few new hires had ever been in a factory, so Ford built the Aircraft Apprentice School on the grounds to familiarize these industrial novices with tools and techniques of high-precision aeronautical manufacturing. Up to 8,000 students per week completed training and reported for work. Among them were farmhands, secretaries, housewives, schoolteachers and grocery clerks.

New housing, better roads and professional training alleviated Willow Run’s employee retention dilemma, but didn’t solve it. A typical month saw as many workers quit as were hired, and 8,200 more were drafted into military service.

Twelve thousand women stepped in to fill the void, each paid the same 85 cents an hour as their male counterparts for nine-hour morning or afternoon shifts. Blacks and other minorities were welcomed and so were immigrants. High school graduates worked the line next to 70-year-olds. Dwarfs, whose physical stature had limited prewar employment opportunities, toiled inside wings, fuel cells and other confined spaces. Out of sheer necessity, Willow Run’s 42,500-member workforce became a model of diversity for future generations.

Rivet gun operator Rosemary Will from Pulaski County, KY, appeared in a Ford promotional film, personifying thousands of women in the nation’s defense industry, collectively known as Rosie the Riveter. Rosemary was among 200,000 southerners who flocked to southeastern Michigan for factory jobs, including 9,500 employed at Willow Run. Hundreds bought their first pair of shoes upon arrival.

Plane Per Hour Pinnacle

The Air Force dictated more performance and safety upgrades for B-24s than any other American warplane. Modifications resulted from lessons learned in fighting fronts and from the need to modify the plane for its multiple roles. Changeovers required onerous delays and costly retooling. Sorensen protested that Willow Run could not function under these strictures. Mass production of B-24s must rely on continuous assembly flow, or they couldn’t be built at all.

The two sides reached an accommodation during the first quarter of 1943. Willow Run stepped up outsourcing of parts production and subassemblies to almost 1,000 Ford factories and independent suppliers while focusing on building B-24s in more predictable designs that minimized shutdowns. Completed planes flew off to field modification centers for fixes, upgrades and customizing. Fifty variants of the aircraft were dispatched to allies throughout the world from these sites.

Production steadily increased, reaching the magical plane-per-hour pinnacle in mid-1944 while accounting for half of all B-24s assembled that year. Manufacturing costs were slashed as man-hours per plane plummeted. It was an historic but ephemeral achievement. Overstocked with B-24s, the Air Force already had canceled contracts with Douglas Aircraft and North American Aviation and would terminate Consolidated Fort Worth by year’s end.

When Germany surrendered on May 7, 1945, only 7,400 employees remained on the Willow Run payroll. The plant closed June 28, ending the Liberator’s brief but epic run, along with Ford’s presence in the aircraft industry. The company resumed automobile production within a week.

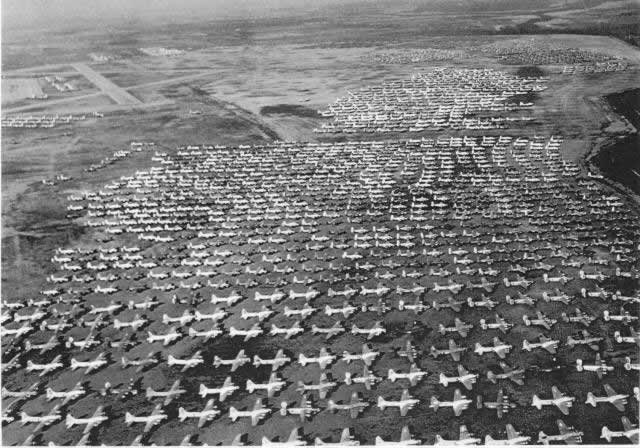

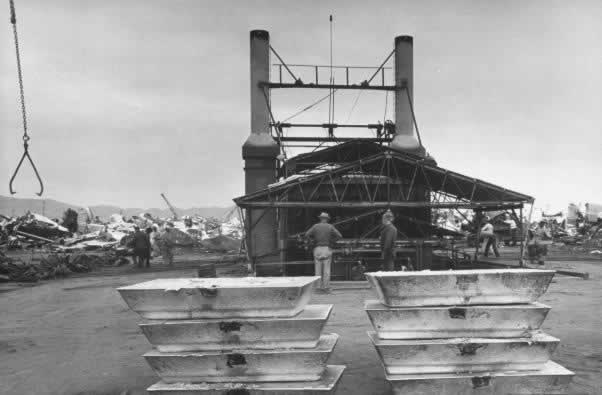

A technological marvel for a new age of aerial warfare, the B-24 was now obsolete. Some 2,500 were parked in an Arizona desert awaiting the day when their aluminum skin and innards would be smelted into ingots for production of coffee percolators, toasters, pots and pans, and myriad other consumer and industrial products to satisfy the ravenous maw of America’s peacetime economy.

Kaiser-Frazer moved into Willow Run and built civilian-style Jeeps, Henry J sedans, and C-119 cargo planes until going under in 1953. General Motors took over and produced transmissions until 2010, when the company declared bankruptcy and moved out. GM’s Chevrolet Division assembled rear-engine Corvairs in a converted warehouse on the grounds during a 10-year run beginning in 1959.

Willow Run Airport became a Midwest destination for passenger airlines until the late 1950s. Warren Avis, a decorated B-24 pilot in the 376th Bombardment Group, opened the nation’s first airport rental car service in the terminal and grew it into Avis Rent A Car Systems. The airport is now home to cargo airlines, charter flights and corporate jets.

A ghostly, decaying reminder of the industrial and military history echoing within its cavernous expanse, Willow Run was demolished in 2014. A 175,000-square-foot section, where B-24s were gassed up and towed out the door, was spared for the future home of the National Museum of Aviation and Technology. In the meantime, visitors to the Yankee Air Museum at the airport can see how the “blacksmith made a watch” and helped win a war.

Transportation history for an electronic age is underway at Willow Run at the American Center for Mobility, where carmakers, suppliers and high-technology companies have banded together to research, develop and test driverless cars that communicate with one another and with traffic signals to avoid accidents and adjust traffic flow. The center includes a proving ground where smart cars react instantly to all manner of potentially dangerous and problematic situations. Unlike menacing B-24 Liberators that took off from the same spot, these silent vehicles are on a mission to save lives and prevent destruction.

US assault troops in an LCVP (landing craft, vehicle, personnel) landing craft approach Omaha Beach, 6 June 1944

US assault troops in an LCVP (landing craft, vehicle, personnel) landing craft approach Omaha Beach, 6 June 1944

Click for larger image

Click for larger image